CP3A ORGANIC SYNTHESIS GROUP

CP3A ORGANIC SYNTHESIS GROUP

Peptidomimetic Chemistry, Photochemistry, Alternative Processes

Process evaluation tools

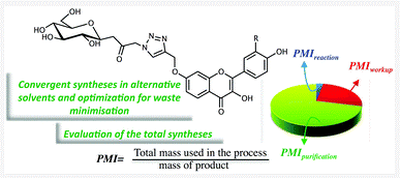

Total synthesis of triazole-linked C-glycosyl flavonoids in alternative solvents and environmental assessment in terms of reaction, workup and purification

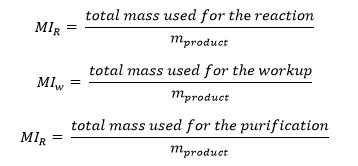

An efficient total synthesis of triazole-linked C-glycosylflavonoids was developed without the use of protective groups in order to promote atom economy, employing alternative solvents, and choosing the least toxic reagents. Aiming to measure the impact of the operation that affects the mass intensity to a greater extent, we envisaged first determining this green metric for the reaction (MIR), the workup (MIW), and the purification (MIP) for each step and then taking advantage of these values to calculate the contributions to the total synthesis.

The process mass intensity was chosen by the American Chemical Society Green Chemistry Institute’s Pharmaceutical Roundtable as a high-level metric for evaluating processes and a tool was proposed to evaluate MI for each individual step and for the whole process of a total convergent synthesis (PMI). This tool allows evaluating the relative proportions due to the substrates and reagents, the solvents, and the aqueous phases in the PMI. We propose a complementary approach to highlight the operation that affects to a greater extent the mass intensity and calculated, for each step, the mass intensity for the reaction (MIR), the workup (MIW), and the purification (MIP):

reference: Total synthesis of triazole-linked C-glycosyl flavonoids in alternative solvents and environmental assessment in terms of reaction, workup and purification. F. Pessel, I. Billault and M.-C. Scherrmann, Green Chem., 2016, 5558-5568. DOI: 10.1039/c6gc01647b

The weight of flash chromatography: A tool to predict its mass intensity from thin-layer chromatography

Purification by flash chromatography strongly impacts the greenness of a process. Unfortunately, due to the lack of the relevant literature data, very often this impact cannot be assessed thus preventing the comparison of the environmental factors affecting the syntheses.

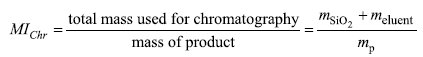

The mass intensity of purification by chromatography (MI Chr) is the ratio between the total mass used to perform the chromatography (i.e., the sum of the mass of silica (mSiO2) and the mass of eluent (meluent) and the mass of the product (mp).

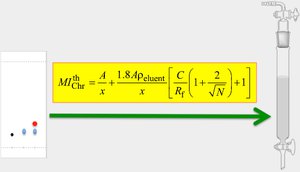

We developed a simple mathematical approach to evaluate the minimum mass intensity of flash chromatography from the retention factor values determined by thin-layer chromatography. In real cases chosen as examples, we have shown that the values were fairly between about 200 and 1200.

We developed a simple mathematical approach to evaluate the minimum mass intensity of flash chromatography from the retention factor values determined by thin-layer chromatography. In real cases chosen as examples, we have shown that the values were fairly between about 200 and 1200.

reference: The weight of flash chromatography: A tool to predict its mass intensity from thin-layer chromatography, F. Pessel1, J. Augé, I. Billault1 and M.-C. Scherrmann, Beilstein J. Org. Chem. 2016, 12, 2351–2357. DOI: 10.3762/bjoc.12.228

Evaluation and improvement of Processes

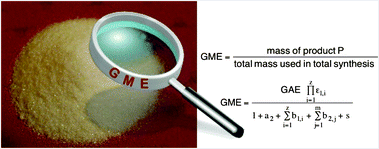

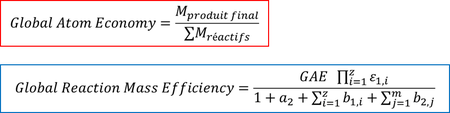

The systematic calculation of green metrics offers an opportunity to evaluate the greenness and then to improve the process. Evaluating the greenness of a product is a social, economical and scientific challenge in chemistry. Green metrics in terms of mass can be determined from the characteristics of all the reactions involved in the total synthesis of the product. We propose a new paradigm to determine the global material economy (GME) of the whole sequence. We have demonstrated that this key metric is directly proportional to the global atom economy (GAE) of the corresponding total synthesis.

The mathematical algorithm to calculate the GME can be applied to any process, whatever the number of the points of convergence in the synthesis, allowing the determination, in terms of mass, of the greenness of a product with respect to all the starting materials involved in the total synthesis.

reference: Determination of the global material economy (GME) of synthesis sequences—a green chemistry metric to evaluate the greenness of products. J. Augé, M-C. Scherrmann, New J. Chem., 2012, 36, 1091-1098. DOI: 10.1039/C2NJ20998e

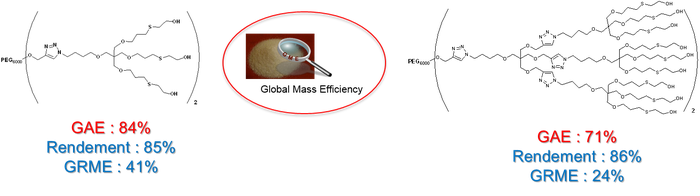

Application to the total synthesis of high loading capacity PEG-based supports

In the synthesis of high loading capacity polymers, the choice of reactions with high atom economy, such as CuAAC and thiol–ene coupling, and optimization of the reaction conditions to increase the yields and reduce the excess of reagents allowed us to increase significantly the reaction mass efficiency (RME) of the different steps.

See also “Chemistry in alternative solvents”

reference: Total synthesis of high loading capacity PEG-based supports: evaluation and improvement of the process by use of ultrafiltration and PEG as a solvent. R. Turgis, I. Billault, S. Acherar, J. Augé, M-C. Scherrmann, Green Chem., 2013, 1016-1029. DOI:10.1039/c3gc37097f